Lessons In Tie Up

I kept looking at my Glimakra loom and puzzling over all the connections. If I shorten this cord, what happens to the shed? If I lengthen that cord, what happens to the shaft it’s connected to? I needed some practice to absorb how the countermarch mechanism on this loom really works. I decided to put on a thirteen yard towel warp. I planned to weave two towels, change the tie up, and repeat six times. While I was at it, I tried turned twill, which I never tried before. And eight shafts, which I also never tried before. That’s a lot of new at once. Some days I sat at the bench just thinking.

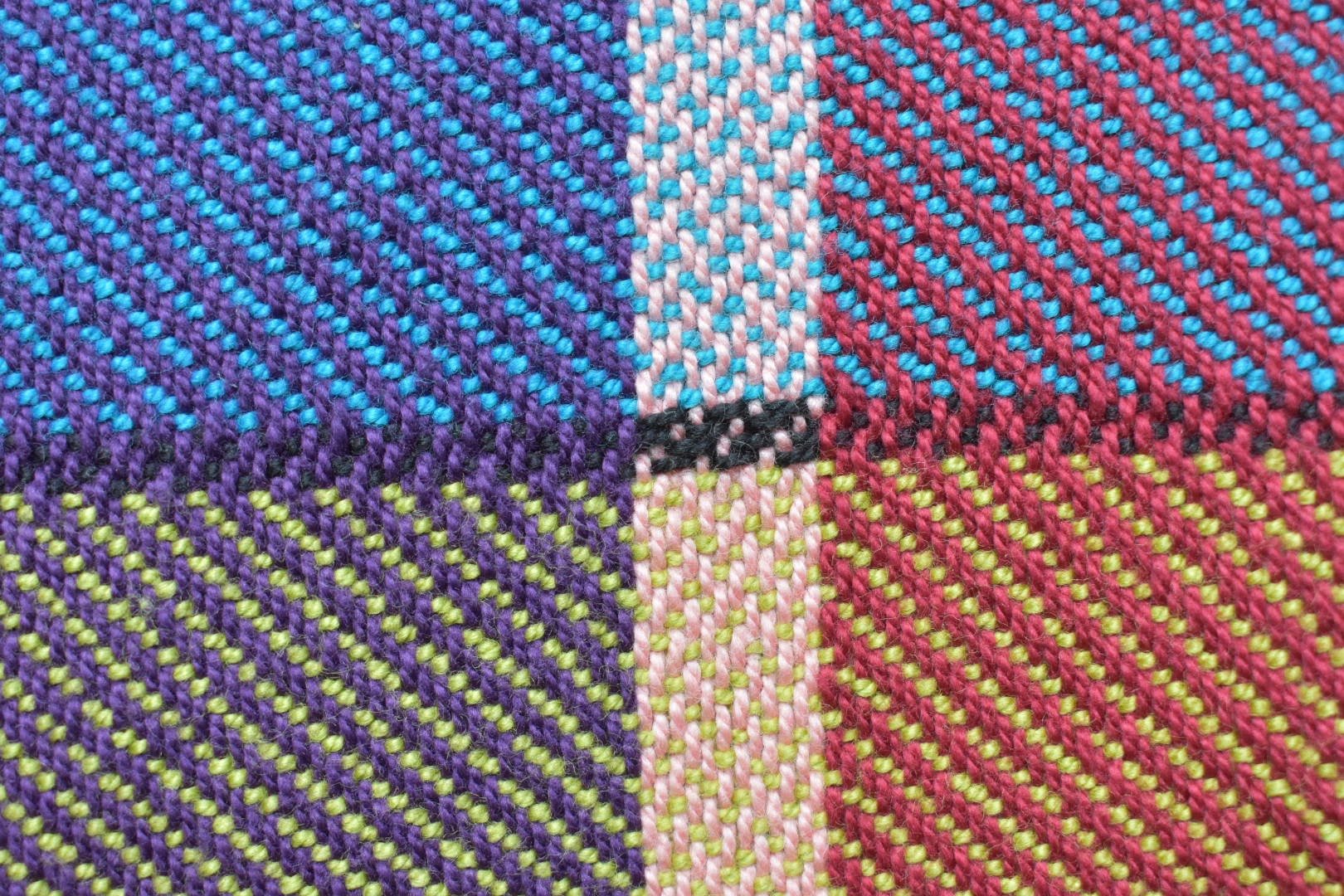

In turned twill the front and the back of the cloth can look quite different.

The front of this towel…

…Is the inverse of the back!

I like the big picture view…

… And the close up detailed view.

…Because everywhere you look, it’s different!

This towel features areas of broken twill next to areas of regular twill.

I like to run my hands across it to feel the texture change as it moves from broken to regular and back to broken.

I like the pinks and blues and reds shaking hands with one another…

… And the gentle grey dancing with the pink and cream.

A softness you can almost feel…

These were just so fun to make!

Now I’m much better, faster and more confident with tie up!

Special thanks to my daughter, who is pretty good with a camera.

How I Made Eight Placemats in Nine Fun Photos

First I wind a warp, counting to make sure I have the right number of threads, and that those threads are all the same length.

The warp is chained to keep all the threads in order while they are transferred to the loom.

The warp threads are spread out, slung up over that high trapeze and weighted so that when I wind them onto the loom, they are all nice and tight.

Here I am threading the loom. Each thread goes through a heddle which will then be raised or lowered to create design while I’m weaving the cloth.

Each thread then gets passed through the reed so that it can be tied onto the front of the loom.

I create the cloth by throwing the shuttle back and forth. When I needed help getting the place mats all the same size, Karen from Warped For Good, graciously explained to me how to make and use the measuring tape you see on the left. (Thank you, Karen!)

The place mats get rolled up at the front of the loom as they are made. They’re coming along! Aren’t they pretty?

Hot off my loom…

Eight place mats - washed, ironed, hemmed by hand, all the same size, and ready to be sent off to Sara who commissioned these to go with her special family dishes!

Longest Warp Ever (For Me) Continued

Finally, finally, this fabric for the curtains in my daughter’s room is off my loom and ready for finishing.

After washing it by hand in the tub to soften the fabric, shrink the cotton and shift the threads, I needed someplace to let it hang dry. It stretches nearly from one end of the basement to the other!

Some quick sewing and…

The finished curtains are perfect for her room!!

It Came!

This big old semi pulled up in front of my house, stopping traffic right as school was getting out, to deliver my very own brand new Glimakra Standard loom. It was all just very exciting!

It came in eight boxes and weighed 340lbs! My daughter helped me unload it off the pallet and carry all the boxes into the living room. That was fun!

Fortunately, the boxes were numbered, so I opened the first couple and started to organize the parts.

Here is the left side all assembled.

My friend used her arms like an octopus to hold up the beams while I slid the right side of the loom into place for the frame to come together. We ended up having to do that twice. Oops.

It was huge! Which was fun!

Then I realized Glimakra accidentally sent me a horizontal countermarche system instead of the vertical one I had asked for. That was less fun.

While I waited for the exchange of parts, Rich helped me to start to build a trapeze like the one I saw when I visited the Vavstuga weaving school. The status of the loom moved back to fun!

I also lashed my warping board to the side of the loom and wound the first warp for it - silk and merino. I’m curious to see what that becomes.

Longest Warp Ever (For Me)

When we moved to our new house a few months ago, my daughter felt her room needed a face lift. It came with this striking wallpaper on an accent wall. She felt she needed a way to tie it in to the rest of her room, so she came to me with her problem.

“Well,” I said, “I could weave some curtains for you.”

I said it without really thinking it through. But, I had said it, so… here it goes.

First, I had to get the Nilus Leclerc loom my sister had given me operational because the little Harrisville loom she had also gifted me didn’t have the width I needed for curtains. That involved sanding down some of the old metal parts, ordering a few “can’t make this loom work without them” new parts, and jamming a piece of scrap wood in the jack box to hold it open. I know that isn’t how one is supposed to do it, but sometimes I just have to solve problems on the cheap.

Before

After

Then I designed, calculated yardage, ordered yarn, and proceeded to wind 540 ends of the longest, finest warp I’d ever wound. At twelve and a half yards, it nearly maxed out my warping board!

When I made the chain to take it off my warping board, I slung it over my shoulder and let it hang down my back so it wouldn’t drag on the floor.

Whenever those threads tried to tangle themselves up as I dressed the loom, I gently reminded them that I was in charge and they needed to behave themselves! Finally I started throwing the shuttle.

It’s still on my loom right now, but here’s a sneak peek at what it’s going to be.

Stay tuned to hear how the curtains turn out!